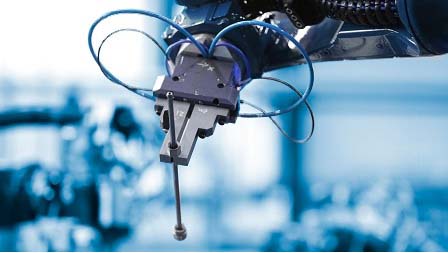

Tube processing

We have acquired our expertise over many years and offer a wide range of possible further processing steps for steel tubes. We actively support you with your plans - from sawing and machining of the tube blank to complex bending and upsetting operations.

We can also reduce eccentricity and improve concentricity by turning and grinding, create complex geometries with processes such as rotary swaging and axial forming, and modify properties with the aid of partial heat treatment.