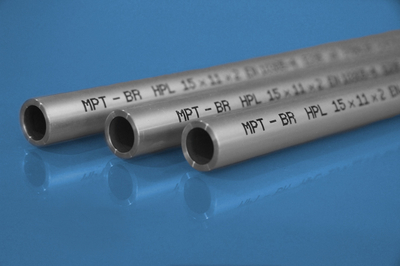

HPL Tubes

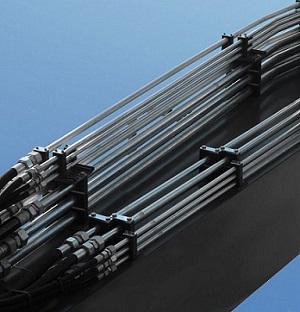

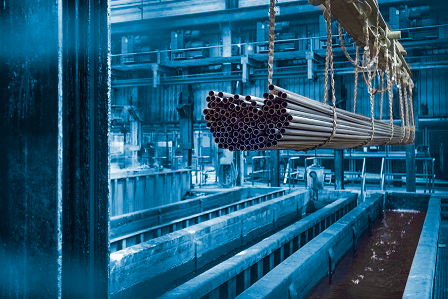

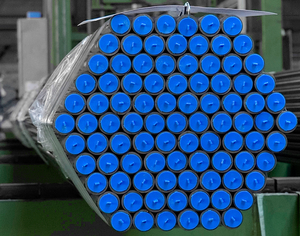

HPL Tubes are seamless cold-drawn precision steel tubes mainly used as pressure lines in hydraulically or pneumatically operated systems. Installation is carried out by detachable and non-detachable connections.

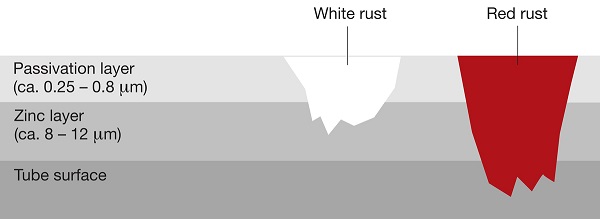

During the operation of hydraulic systems, changes in velocity and pressure of the flowing medium occur under operating conditions. The changes in velocity cause pressure surges that lead to a superposition with the static internal pressure. Thus, the tubing is usually subjected to pulsating stresses. When designing the tubes for such systems, the actual stress profile under service conditions must be taken into account. If lightweight construction requirements or maximum operating pressures are of importance, we will be pleased to inform you about our HPL +N Duro solutions. Furthermore, we offer MW-protect® - an optimized corrosion protection with a particularly long-lasting protective effect.

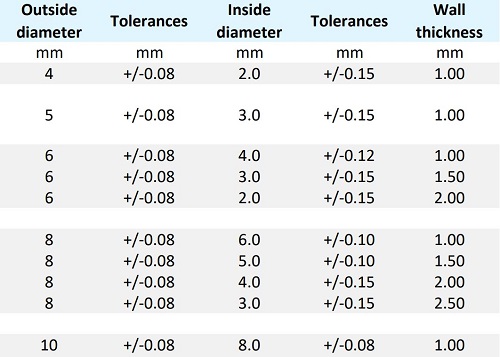

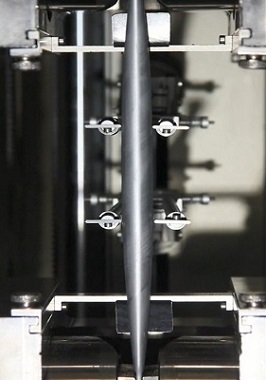

The dimensions and requirements of the tubes on this website are aligned with EN 10305-4 "Seamless cold-drawn tubes for hydraulic and pneumatic power systems".

The detailed delivery program, including dimensions and tolerances, was created in accordance with EN 10305-4 "Seamless cold drawn tubes for hydraulic and pneumatic power systems“ and also takes into account established dimensions in hydraulics and pneumatics.

The design of HPL tubes can be carried out according to the calculation basis of DIN 2413. We are pleased to be at your service for questions regarding the design according to DIN 2413 taking into account your operating conditions.